Simone Way

Wisdom and Sincerity Make Way for Craftsmanship,

A Unique Value Created Over a Long Period of Time,

All Answered with Simone

Simone Way

Why Not Us?

With a few pieces of samples to show our competitiveness, we firstly visited to the Donna Karan headquarters in New York. Positive responses to quality, price, and trade terms were initially expressed by the marketing manager. That being said, they didn’t want to initiate the trade because all the bags were made in Korea, not made in Italy or conventional origin of fashion products. To make matters worse, a trade with Simone who has limited experience manufacturing luxury handbags never took place between us. Disappointed, but not defeated, we didn’t give up. We kept on persuading them by explaining that Asia will take much of the share for the manufacturing base in the handbag manufacturing market, and we conveyed to them that currently long haul Italian atelier started its history from virtually nothing, so why not us? Finally, we succeeded in receiving the very first order of 120 pieces of handbags. It was a very small volume at our inception that allowed us to become a center of handbag production in Asia. Eventually such a small seed planted momentum so that we could grow concurrently with the emergence of accessible luxury in the US market.

Simone, the First Mover to ODM from OEM Started to Develop Product Designs and Materials

Donna Karan’s designers travelled to Simone headquarter for the purpose of developing product design. We proactively suggested new material sources to our customers after anticipating potential problems in material handling when designers followed up on samples.

The utmost care was devoted to our customers in order for us to become a unique ODM company in global market.

Production Base Shift to China

Ever since our story spread among customers,various luxury fashion brands approached us to looking to do business with Simone. We persuaded our buyers to supply our products to consumers in China and moved our production base there as well. We sent Korean craftsmen to the production base to maintain quality control and pass along our extensive experience and expertise in handbag manufacturing to demolish the stereotype of products that are “Made in China.”

Simone’s Capabilities Captured the Mind of Several European Luxury Brands

The president of LVMH and their company representatives held a blind test to distinguish the difference between products made in Italy and handbags made by Simone. The result of the test was 50:50. This gave our company the chance to spread awareness about our world-renowned quality, breaking the perception that Italy was by default the best in the industry. As a result, several European brands as well as American brands began looking to work with Simone.

Introduced QA (Quality Assurance) System

to Become a Full Service Company

Since mid-2000s we adopted a QA (Quality Assurance) system that is more advanced than simple QC (Quality Control). We ensured the quality of products by assigning a line manager to each process, who is responsible for each process ranging from product planning to production, inspection, and shipment. Simply said, we are a full service company when it comes to handbag manufacturing.

Various handbag brands newly launched in the market were attracted by the full service that we provide, and they came to us requesting to be their launching partner.

Facilitate Automation Process Embracing Craftsmanship of Our Artisans

We aim to standardize the quality of mass production to offer the same high-quality at each and every base, regardless of the origin of the products while we explore and expand our production base to Vietnam, Indonesia, and Cambodia.

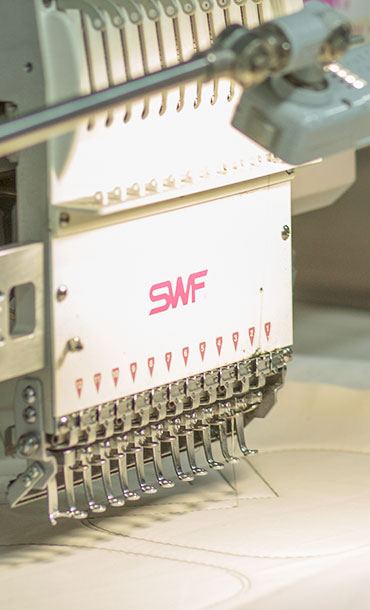

We are exercising a tremendous synergy effect with the QA system due to automating the process that requires man-made work (ie. UV Dryer Machine).

Recognized as a Company Manufacturing Innovation (IDM)

Not settling for the glorious number one title in the world, we will strive to improve the efficiency of our manufacturing no matter what title we are given now and beyond. We developed various innovative manufacturing tools to increase our efficiency and quality of products: 50 different kinds of hammers to trim handbag material, rollers in different diameters, computerized sewing machines for hand sewing quality, and a drying conveyor belt made by calculating temperature and speed. These products helped us become recognized as a manufacturer (IDM: Innovative Development Manufacturing) that develops innovative products in the global fashion industry.